products

GUITAR PICKUPS

How they work?

In the simplest example you have a magnet wound with a coil and you create a magnetic field. When the guitar string vibrates it impacts the magnetic field causing a change in voltage. The “strength” or “weakness” of the magnet impacts the sound of the guitar pickup. There is an entire industry built around capturing a myriad of sounds from “vintage”, “smooth”, “bright”, “brassy”, “even” and list goes on.

What magnetic materials are used for pickups?

When selecting a magnet, you should understand the unit “strength” of the magnet fields is given in Tesla (T) in the SI system and in Gaussian-cgs system is measured with the unit gauss (G).

Alnico 2, 3 and 5 are the most common and sizes of .187”, .195” diameter x .450” – .875” in length are typical. Shorter lengths are not feasible because there is not enough magnetic material to hold enough charge.

Alnico was developed in the early 1930’s and rapidly replaced magnetized steel. Alnico is an acronym for a family of iron-based magnet alloys which also contain aluminum (Al), nickel (Ni), cobalt (Co), hence, al-ni-co. The magnets also contain copper (Cu) and, sometimes, titanium (Ti).

Another magnetic material use in pick-ups are Ceramic magnets that were developed in the 1950s. Ceramic magnets are also known as hard ferrites or ferrite magnets, which are composed of primarily iron oxide, Fe2O3. The two common compositions are: strontium ferrite, SrFe12O19 (SrO·6Fe2O3) and barium ferrite BaFe12O19 (BaO·6Fe2O3). Typically, people select ceramic when they are looking for a lower cost solution.

For other pickup applications some people find that FeCrCo has a similar sound, and this material is available from Allstar. The two main FeCrCo grades – FeCrCo12/4 (also known as FeCrCo1) & FeCrCo44/4 (also known as FeCrCo5) are the most common materials used.

We also provide NdFeB and SmCo magnets for pick-ups by special order.

Selecting the Sound

Selecting the specific magnetic grade is the way to achieve unique tones and resonance. There are many opinions on what magnet grades creates what sound. Other factors such as chemical composition, physical dimensions and thermal properties also impact the type and quality of the sound.

For example, Ceramic is considered to create a sharper, brighter clearer sound because of the higher output than alnico. This makes it a good material to use with heavy distortion. Unfortunately, ceramics are usually linked to low-cost equipment and can sound brittle and fuzzy.

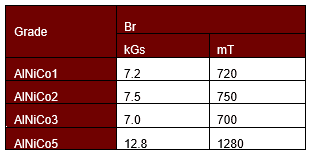

Alnico is one of the most popular pickup materials used and Table 1 shows the relative strengths.

In comparison to Ceramic, Alnico pickups are often described as smooth with softer tones.

The naming convention of Alnico 3 is misleading because it has the weakest magnetic strength. In a pickup is has been described as soft on the bottom end and smooth through the middle tones.

In addition to diameter and length considerations the edge finish on the ends also impacts the sound.

Magnets can be specified as

- Edge break – as machined

- Tumbled – put through an operation to remove the sharp edge (Radii ~0.005” on all edges)

- Bevel – small – is said to produce “Vintage” sounds (Chamfer 0.010” x 45° on one side)

- Bevel – larger – is describe as a “Modern” sound (Chamfer 0.020” x 45° on one side)