industries

Oil & Gas

Magnets are crucial in everything from discovery to recovery to maintenance and safety. Our engineering and machining skillsets help our partners to design and manufacture products for immediate application and far into the future.

Downhole Sensors Tools and Corrosion Monitoring

APPLICATION

Rare earth magnets are used in various downhole sensors and measurement tools, including pressure and temperature sensors, flow meters, and casing inspections, to ensure accurate data collection and monitoring. Corrosion monitoring tools are used to detect and monitor the presence of corrosion or metal loss within pipelines and equipment, helping to prevent leaks and failures. Inspecting and maintaining the integrity of a pipeline and storage tanks is a fundamental requirement of any upstream, midstream, and downstream O & G operations.

SOLUTION

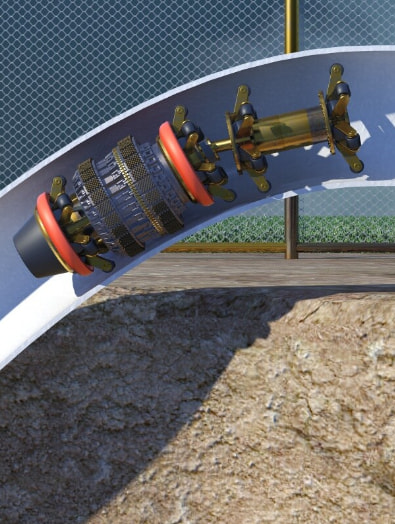

Allstar specializes in the manufacture of Pipeline Inspection Gauges (PIGs), Magnetic Flux Leakage MFL tools and Pipeline Pigs. They have the capability to customize sets of magnets to create the magnetic fields needed for the detection of corrosion and metals loss in pipelines. These same customized fields are also required in PIGs to detect pressure, temperature and other critical performance indicators of a pipeline system.

Casing Collar Locators (CCL)

APPLICATION

CCL is a magnetic downhole device that is used to detect changes in metal thickness to confirm or correlate treatment depth using known reference points on the casing string. It is mainly used for depth control and depth correlation.

SOLUTION

Allstar understands how to create the magnetic field to optimize the sensitivity and accuracy of the CCL magnetic assemblies. We supply both the magnets and coils needed for CCL tools and can provide a custom turnkey solution for your needs.

Wellbore Stability and Magnetic Separation tools

APPLICATION

These applications rely on the uniformity of rare earth magnets in harsh environments. Magnets are used to stabilize wellbores by controlling the movement of metallic debris and particles, preventing them from interfering with drilling operations or causing wellbore instability. Magnetic separators are used to remove ferrous contaminants from drilling fluids and oil and gas production streams. This helps improve the quality of the extracted fluids and prevents damage to downstream equipment.

SOLUTION

Allstar supplies various magnets and assemblies used for wellbore cleanout and filtration tools. An important consideration when assembling and producing these components is the ability to create and measure custom fields. The strength of these fields directly impacts the performance and effectiveness of the tools which reduce maintenance cost and avoid abrasion damage to critical components.

Submersible Pumps

APPLICATION

Electric submersible pumps (ESPs): ESPs are used to generate the magnetic fields necessary for efficient and reliable motor operation. These pumps are commonly used for lifting oil and water from deep wells.

SOLUTION

A major component for the systems is the Permanent Magnet Motor (PMM). Rare earth magnets are used in the rotor section both for their stability and reliability in challenging environments. Allstar manufactures efficient and cost competitive custom PM rotors.

Perforation Guns

Application

Perforation guns play a crucial role in the oil and gas industry by aiding in the extraction of hydrocarbons from underground reservoirs. These specialized tools are used to create precise holes or perforations in the well casing and surrounding rock formations. This process allows oil and gas to flow into the wellbore and be brought to the surface, ultimately enhancing well productivity and efficiency by establishing a direct connection between the reservoir and the well.

Solution

Allstar Magnetics specializes in advanced perforation guns designed for the oil and gas industry. These guns are built to withstand extreme downhole conditions and feature innovative designs that enhance efficiency, safety, and reliability during the perforation process. By integrating cutting-edge magnetic technology and rigorous quality control, Allstar ensures that their perforation gun components deliver consistent, high-quality results, crucial for successful well completion and reservoir management.

Certifications & Compliance

Sales Terms & Conditions

- California Proposition 65 Compliance Statement (12/2023)

- Conflict Minerals Reporting Template – CMRT 6.4 (07/2024)

- REACH Compliance (10/2024)

- RoHS Statement (08/2022)

- PFAS Declaration (05/2024)

IMA – The International Magnetics Association

MMPA

TTA

Trust us for all your magnetic component needs.

We’ll expertly guide your ideas from prototype to design, guaranteeing top quality, customized products that perfectly align with your specific requirements.

Allstar magnetics is Your Strategic Partner

Whatever your manufacturing challenges might be, Allstar Magnetics’ competitive advantage includes product strategy, conceptualization, design engineering, material technology, test engineering as well as well as full production & manufacturing services.