November 2025: Issue 4

Welcome to Magnetic Matters

At Allstar, strong relationships and creative problem-solving go hand in hand. This month, CEO Tyee Harpster reflects on the power of in-person partnerships, and our team showcases that same spirit with a custom adhesive curing solution built for smarter results.

At the Core: Notes from the CEO

The Real Infrastructure of Our Business

By Tyee Harpster, President and CEO

After five flights, ten hours of drives, six hotels, and forty-seven hours of meetings, I came home from Asia feeling tired—but mostly grateful. This trip through Singapore, Shanghai, Ningbo, and Bangkok was a whirlwind of collaboration, problem-solving, and connection.

From early-morning factory tours to late-evening dinners, every moment was a reminder that relationships are the real infrastructure of our business. Walking the production floor together with our partners, reviewing details, and planning for what’s next builds a kind of trust that simply can’t be replicated through email or video calls.

|  |  |  |

When we understand our partners’ capabilities firsthand, our customers benefit. We can anticipate challenges before they happen, find smarter sourcing strategies, and ensure reliability across every part of our supply chain. That’s what makes Allstar’s network so strong—and why face-to-face connection remains at the heart of how we do business.

And yes, even amid all the meetings, I managed to bring home one unexpected souvenir—a Labubu—proof that every trip brings its own surprises.

Thanks to everyone who welcomed me along the way and to the Allstar team who kept things running smoothly back home. Together, we’re proving that excellence comes not just from processes, but from people—and the relationships we build along the way.

Smarter Solutions in Action: Custom Tooling for Adhesive Curing

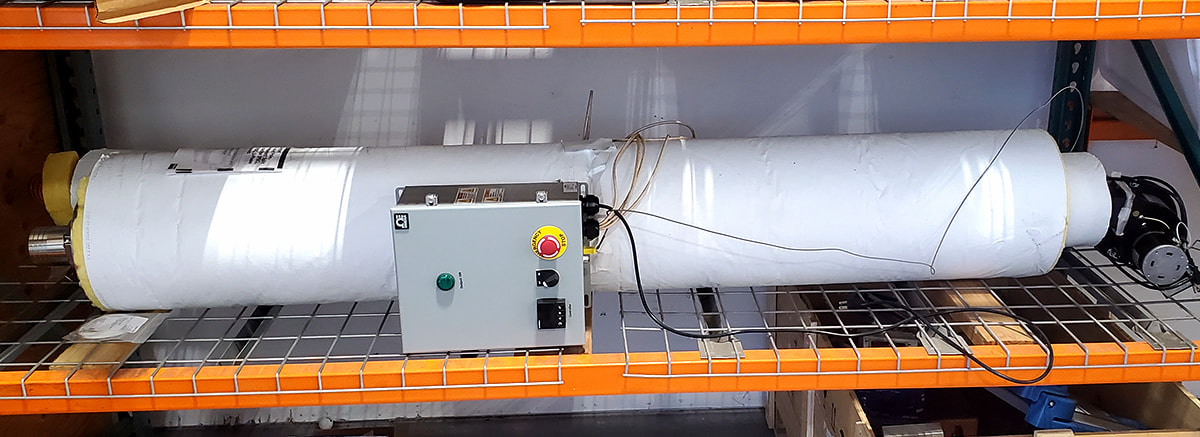

At Allstar Magnetics, we know that every project brings unique challenges. Recently, a customer came to us with a requirement: cure adhesive on specialized magnets and large assemblies at a specific temperature and amount of time. Normally, this would call for a massive industrial oven—an expensive and space-consuming solution.

Instead of passing that cost along, our team designed and built a custom oven in-house. By combining electrical and mechanical expertise, we created a flexible system that not only handled this project but can be adapted for future needs. We collaborated with the customer on the initial design of the unit, and now Allstar is refining it further—adding a control box to regulate and modify heat for even more precision.

The result? A solution that was faster, more cost-effective, and tailored to the customer’s needs. Just as important, this innovation adds long-term value: we now have a scalable capability to support similar projects going forward.

This project is a great example of how Allstar goes beyond being just a supplier—we’re a partner who listens, innovates, and finds better ways to solve problems.

Have a challenging project on your desk? Let’s start a conversation about how Allstar can help you achieve a smarter, more cost-effective solution.