industries

Audio/Music

Permanent magnets are used for speakers, custom transformers are used for amplifiers, and guitar magnets are used for pickups. The experience and capabilities in this segment are unparalleled.

Guitar Pickup Magnets

In electric guitars, permanent magnets, particularly Alnico, are used in pickups to enhance sound quality and output. These magnets generate a focused magnetic field that interacts with the guitar strings, converting their vibrations into electrical signals with greater sensitivity and clarity. As a result, pickups equipped with these magnets offer improved tone definition, higher output, and reduced noise interference.

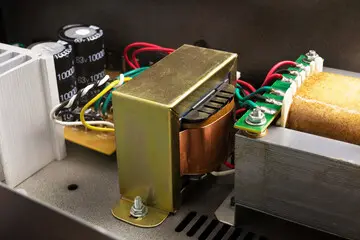

Audio Transformers

Custom-wound magnetics are essential for transferring electrical signals between circuits while preserving audio quality. These transformers use wire coils wound around a magnetic core to convert high-impedance signals into low-impedance signals, and vice versa, allowing compatibility between different audio devices. Through electromagnetic induction, they maintain faithful frequency response to the original sound, reducing distortion and noise. They are crucial in applications such as microphone preamps, guitar/bass amps, and various audio processing equipment, ensuring clear and balanced sound reproduction.

Speakers

Rare earth magnets, particularly neodymium magnets, are widely used in high-performance speakers because of their strong magnetic fields and compact size. In speaker systems, these magnets improve the efficiency and power of the voice coils, which convert electrical signals into sound. The strength of rare earth magnets allows for the production of smaller, lighter, and more powerful speakers with improved sound quality and greater fidelity. This technology is essential for high-end audio equipment where clarity and precision are crucial, enabling the creation of rich, detailed soundscapes in everything from home audio systems to professional sound reinforcement.

Certifications & Compliance

Sales Terms & Conditions

- California Proposition 65 Compliance Statement (12/2023)

- Conflict Minerals Reporting Template – CMRT 6.4 (07/2024)

- REACH Compliance (10/2024)

- RoHS Statement (08/2022)

- PFAS Declaration (05/2024)

IMA – The International Magnetics Association

MMPA

TTA

Trust us for all your magnetic component needs.

We’ll expertly guide your ideas from prototype to design, guaranteeing top quality, customized products that perfectly align with your specific requirements.

Allstar magnetics is Your Strategic Partner

Whatever your manufacturing challenges might be, Allstar Magnetics’ competitive advantage includes product strategy, conceptualization, design engineering, material technology, test engineering as well as well as full production & manufacturing services.