Powering Research with Precision Magnet Solutions

October 2025: Issue 3

Welcome to Magnetic Matters

In this edition we’re highlighting what really made the difference in a national laboratory’s next-generation accelerator project: supply chain management.

Read the full case study below and join the conversation on LinkedIn to see how smart supply chain management drives innovation across industries.

Powering Research with Precision Magnet Solutions

See how Allstar Magnetics helped a national lab keep its next-generation accelerator project on track by delivering highly specialized magnets exactly when and where they were needed.

Client

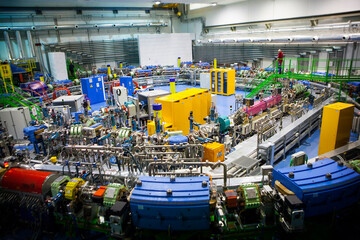

Our client is a U.S. Department of Energy national laboratory in New York, operating one of the nation’s most advanced particle accelerators. For over 20 years, they’ve trusted Allstar Magnetics as a strategic partner to supply high-energy magnetic components essential to their accelerator’s mission. Their work requires extremely precise engineering to channel and control energy beams in research aimed at unlocking new scientific discoveries.

Project Overview

Allstar Magnetics partnered with the lab as they developed critical components for a next-generation underground accelerator prototype—a project with the potential to reshape the future of accelerator research. The magnets required for the prototype were large, highly specialized, and needed to be integrated into custom steel assemblies—difficult to source, produce, and coordinate across multiple suppliers.

Timing was everything: the lab needed components delivered in sequence with their build schedule. Too early meant costly on-site storage. Too late meant research delays, stalled experiments, and wasted resources.

Timing was everything: the lab needed components delivered in sequence with their build schedule. Too early meant costly on-site storage. Too late meant research delays, stalled experiments, and wasted resources.

They needed a partner who could own the full supply chain—anticipating potential issues, consolidating multiple moving parts, and ensuring that the right products arrived at the right place, at exactly the right time.

Our Approach:

Allstar Magnetics served as a turnkey partner, overseeing sourcing, production, shipping, and delivery within one cohesive engagement. With a single call, the client entrusted the project to Allstar, confident that every detail would be managed.

Our coordinated approach included:

- End-to-end sourcing and production – Engineering and manufacturing high-energy magnets and custom steel housings to exact specifications.

- Precision logistics – Aligning shipping and delivery with the lab’s rebuild timeline so components arrived when needed—never too soon, never too late.

- Supply chain simplification – Coordinating vendors, schedules, and assembly into one streamlined process.

- One-stop accountability – Consolidating all work into a single invoice, eliminating administrative burden and freeing the client to focus on research.

In short, Allstar managed every step: sourcing, production, shipping, and delivery—executed as a single, seamless operation.

Results:

The accelerator’s beta efforts advanced seamlessly, enabling researchers to achieve higher beam precision, focus more energy on the system, and continue driving scientific discovery.

Because Allstar handled the complex sourcing, production, and delivery, the client’s engineers were able to stay focused on high-energy research rather than manufacturing and supply chain issues.

This partnership’s impact:

- Maintained uninterrupted research schedules.

- Delivered complex, high-spec components on time.

- Strengthened a 20+ year partnership built on trust and execution.

Conclusion:

Allstar Magnetics is more than a supplier—we are a turnkey solutions partner. From sourcing and production to shipping and delivery, we take on complexity so clients can focus on their mission.

For high-energy physics, aerospace, industrial manufacturing—or any application where precision and timing are critical—Allstar delivers the confidence of knowing every detail will be right the first time.

Ready to power your next breakthrough?

Contact Allstar Magnetics to discover how our turnkey approach can simplify your supply chain and deliver the results your team needs to succeed.