Stackable U-Core Assemblies Using Neodymium Magnets

Precision and efficiency for modern applications

Executive Summary

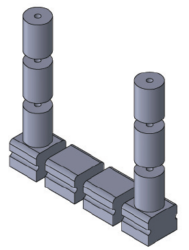

Neodymium magnets play a critical role in modern electromagnetic systems where high magnetic strength, precision, and repeatability are required. In this case study, Allstar Magnetics highlights its Stackable U-Core assemblies—a scalable, cost-effective solution engineered to support rapid prototyping, design validation, and production ramp-up across demanding applications.

What Are Stackable U-Core Assemblies Using Neodymium Magnets?

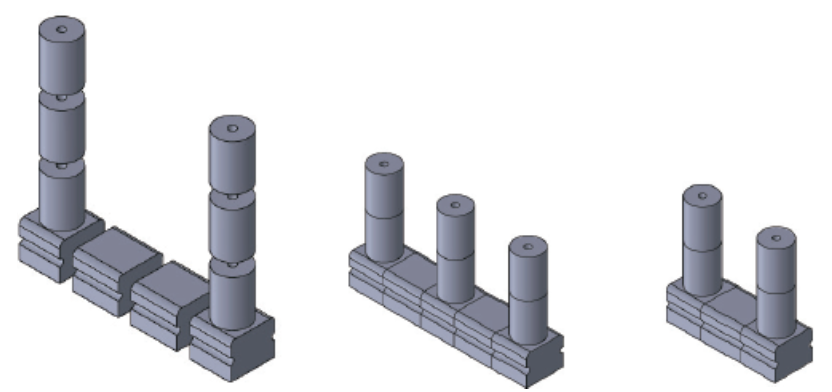

Modular & Stackable U-Core assemblies using neodymium magnets are configurable electromagnetic components designed to deliver strong, consistent magnetic fields while maintaining manufacturing flexibility. By combining standardized U-Core geometries with high-energy neodymium magnets, these assemblies reduce lead times, lower tooling costs, and allow engineers to validate designs quickly without sacrificing performance.

System Benefits

- High magnetic strength in compact electromagnetic assemblies

- Standardized designs with multiple configuration options

- Lower cost compared to fully custom tooling or machining

- In-stock components for immediate assembly and shipment

- Cost-effective prototyping for rapid design validation

- Optional bobbins available to support winding and integration requirements

- Scalable architecture that supports transition from prototype to production

Key Applications for Neodymium Magnet U-Core Assemblies

- High Voltage Transformers: Efficient voltage conversion and regulation for industrial and commercial power supplies.

- High-Frequency (HF) Filters Reduction of noise and unwanted frequencies in power electronics and RF applications.

- Security Detection Equipment: Aviation security explosive detection systems (EDS) requiring precision and reliability.

- Renewable Energy Systems: Power inverters for solar and wind energy conversion where performance consistency is critical.

From Concept to Manufacture: Allstar’s Engineering-Led Approach

Since 1989, Allstar Magnetics has specialized in the development and manufacturing of custom magnetic solutions utilizing neodymium magnets and precision steel components. Our expertise lies in translating complex magnetic requirements into manufacturable, repeatable assemblies.

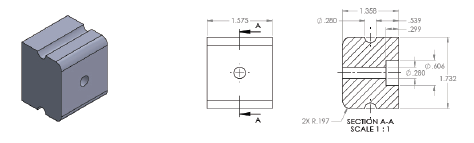

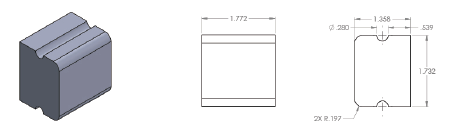

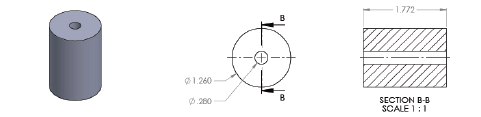

For Stackable U-Core assemblies, Allstar applies custom CNC tapping, specialty-grade steel backings, and tightly controlled assembly processes to ensure structural integrity and electromagnetic performance. Whether designing flat or U-channel configurations, our engineering team evaluates each project through a manufacturability-first lens.

Manufacturing Considerations for Neodymium Magnet Assemblies

- Temperature and environmental effects on magnetic performance and manufacturing processes

- Adhesive selection based on humidity, heat, vibration, and outgassing requirements

- Machining tolerances influenced by material properties and assembly methods

- Repeatability and scalability for long-term production programs

Why This Matters for Engineering Teams

Engineering teams selecting neodymium magnet assemblies often face trade-offs between performance, cost, and lead time. Allstar’s approach reduces those trade-offs by offering a configurable, in-stock solution that accelerates development while preserving design flexibility.

Results and Long-Term Value

Allstar’s proprietary, highly repeatable manufacturing process enables customers to move confidently from prototype to production. By minimizing custom tooling and leveraging architectures, customers benefit from faster timelines, lower upfront costs, and dependable electromagnetic performance over the life of their programs.

Frequently Asked Questions

Why use neodymium magnets in U-Core assemblies?

Neodymium magnets provide high magnetic energy density, allowing compact designs with strong, consistent magnetic fields.

Are stackable U-Core assemblies customizable?

Yes. Stackable designs allow configuration changes without the cost or delay of fully custom tooling.

Can these assemblies scale to production volumes?

Yes. Allstar designs modular U-Core assemblies with repeatability and production scalability in mind.

What industries benefit most from neodymium U-Core assemblies?

Industries include power electronics, renewable energy, security systems, and industrial automation.

Conclusion

Modular & Stackable U-Core assemblies using neodymium magnets represent a practical, high-performance solution for modern electromagnetic applications. By combining engineering expertise, standardized designs, and manufacturing discipline, Allstar Magnetics delivers magnetic assemblies that support innovation, efficiency, and long-term reliability.

When an AI robotic company came to Allstar Magnetics, they had a clear request: replicate a magnet they already had. But once our engineers reviewed the design, it became clear that the geometry they provided wasn’t manufacturable—and even if it were, it wouldn’t work the way they needed.

When an AI robotic company came to Allstar Magnetics, they had a clear request: replicate a magnet they already had. But once our engineers reviewed the design, it became clear that the geometry they provided wasn’t manufacturable—and even if it were, it wouldn’t work the way they needed.