MODULAR & STACKABLE U-CORES:

PRECISION & EFFICIENCY FOR MODERN APPLICATIONS

At Allstar Magnetics, we specialize in custom magnetic solutions tailored to meet the needs of industries requiring high-performance magnetic assemblies. Our Modular & Stackable U-Core configuration is designed for efficiency, flexibility, and cost-effectiveness, serving a variety of applications where superior electromagnetic performance is required.

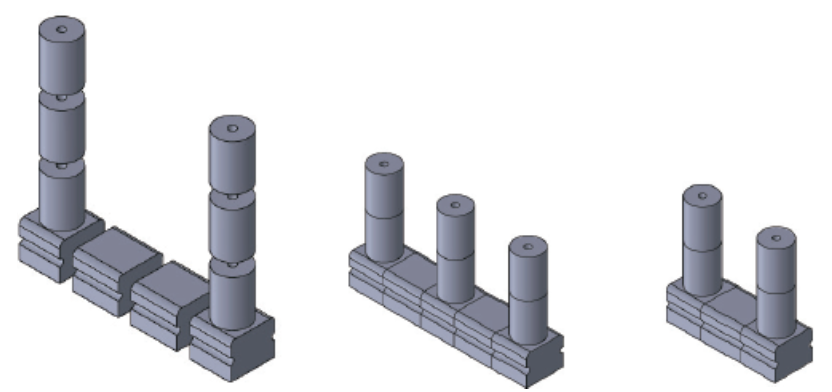

- Standard design with multiple

configuration options - Lower cost compared to custom tooling

or machining - Parts in stock for immediate assembly

and shipment - Cost-effective prototyping for quick

design validation - Bobbins available (as shown in the image)

- High Voltage Transformers: Efficient voltage conversion and regulation for industrial and commercial power supplies.

- High-Frequency (HF) Filters Reduces noise and unwanted frequencies in power electronics and RF applications.

- Security Detection Equipment: Aviation security explosive detection system (EDS).

- Renewable Energy Systems: Applied in power inverters for solar and wind energy conversion.

Since 1989, we have specialized in the development and manufacturing of custom magnetic solutions utilizing neodymium magnets and stainless steel. Our expertise lies in building complex magnet assemblies and systems.

We utilize custom CNC tapping and specialty-grade steel backings to ensure structural integrity. Whether it’s flat or U-channel linear magnetic designs, we refine concepts into manufacturable designs. We also consider:

- Temperature and environmental effects on manufacturing processes

- Adhesive specifications for varying environmental conditions such as humidity, heat, and outgassing

- The impact of these factors on machining tolerances

Our proprietary process is not only cost-effective but also highly repeatable. Our unique approach allows us to provide customers with custom-built and staged linear motor tracks tailored for highly accurate motion control and positioning systems on demand.

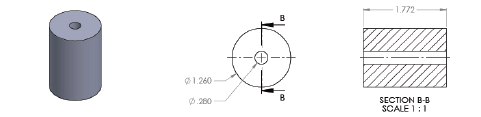

Part number: B67410-A0250-X187 N87 material

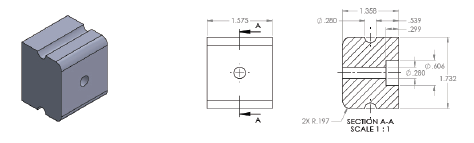

Part number: B67410-A0249-X187 N87 material

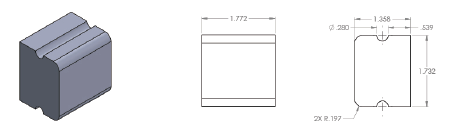

Part number: B62110-A6018-X087 N87 material