IRON CHROME COBALT (FECRCO) – A CASE STUDY

IRON CHROME COBALT (FECRCO):

Explore the Tone-Shaping Potential of FeCrCo for

Guitar Pickups

Iron Chrome Cobalt (FeCrCo) is a cobalt-chromium-based magnetic alloy originally developed as a replacement for CuNiFe. It is now gaining popularity in the audio and guitar industries as a high-performance alternative to AlNiCo—delivering vintage tone with modern manufacturability.

Key Properties

| Property | Value Benefit | Value B |

| High Remanence (Br) | Warm tonal output, comparable to AlNiCo pickups |

| Low Coercivity (Hc) | Easily magnetized and shaped for precision field control |

| High Temp Resistance | Stable performance across a wide range of temperatures |

| Low Temp Coefficient | Predictable behavior under changing conditions |

| Corrosion Resistance | No coating required—ideal for long-term durability |

- Ductile and Formable: Can be rolled, stamped, and bent before heat treatment

- Machinable: Easier to process than traditional AlNiCo or rare earth alloys

- Thin Strip Capability: Can be formed into very thin strips for compact designs

- No Post-Coating Required: Simplifies production and reduces cost

|

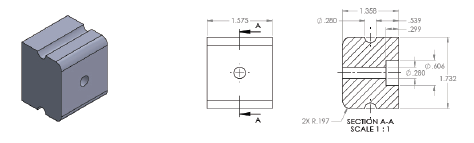

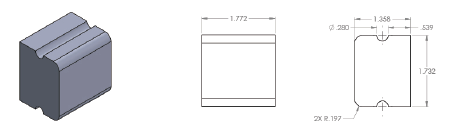

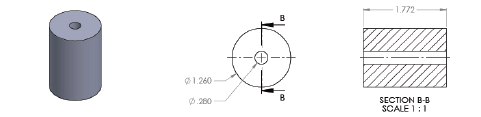

Available Forms:

Recommended Applications

Why Choose FeCrCo?

FeCrCo offers the tonal character of classic materials with the manufacturability modern pickup designers need. It bridges the gap between vintage warmth and production flexibility—making it an excellent choice for builders and engineers in the audio space.

|

|

FeCrCo12/4 (referred to as FeCrCo1) and FeCrCo44/4 (referred to as FeCrCo5) are the two most commonly used Iron Chromium Cobalt materials. The other materials are available but may have a larger min order quantity.

Contact UsLooking for a material that delivers vintage tone with modern manufacturability? Contact Allstar Magnetics—your trusted partner for FeCrCo prototyping and full-scale production, specializing in magnetic solutions for audio and guitar applications..