by Karla Takasumi | Dec 17, 2021 | Industry News

Posted December 17, 2021

METALS FORECAST

This last year has seen large fluctuations in metals pricing for components used in the manufacture of magnetic cores and rare earth magnets. Factors driving the prices up including supply shortages, increased production costs and the continued growing demand.

Rare Earth Forecast:

| August | September | October | Year to Date |

PrNd

% Change | -0.7% | -1.6% | 16.4% | 45.5% |

DyFe

% Change | -0.8% | 4.1% | 5.6% | 36.0% |

Cobalt

% Change | -2.9% | 4.9% | 8.0% | 31.6% |

In the month of November, PrNd rose by 15.8% and Cobalt by 7.6%.

[vc_separator type=’normal’ position=’center’ color=’#8e2321′ thickness=’2′ up=’30’ down=’20’]

Magnetic Cores Forecast:

| Part No. | Item Description | UoM | Product Cat. | Sub Cat. |

| 0059122A2 | OD17/10/6 EDGE CORE 026 PERM

| PCS

| Powder Core

| EDGE Core

|

| 0059083A2 | OD40/24/15 EDGE CORE 060 PERM | PCS

| Powder Core

| EDGE Core

|

0059894A2

| OD 28/14/12 EDGE CORE 060 PERM

| PCS

| Powder Core

| EDGE Core

|

0059254A2

| OD40/24/15 EDGE CORE 125 PERM

| PCS

| Powder Core

| EDGE Core

|

0059120A2

| OD17/10/6 EDGE CORE 125 PERM

| PCS

| Powder Core

| EDGE Core

|

0059381A2

| OD17/10/6 EDGE CORE 060 PERM

| PCS

| Powder Core

| EDGE Core

|

0059930A2

| OD27/15/11 EDGE CORE 125 PERM

| PCS

| Powder Core

| EDGE Core

|

0059380A2

| OD17/10/6 EDGE CORE 125 PERM

| PCS

| Powder Core

| EDGE Core

|

0059848A2

| OD20/13/6 EDGE CORE 060 PERM

| PCS

| Powder Core

| EDGE Core

|

In the year to date, Nickel rose by 18.1% and Zinc by 18.7%.

[vc_separator type=’normal’ position=’center’ color=’#8e2321′ thickness=’2′ up=’30’ down=’20’]

We highly recommend that customers place blanket or other long-term contracts to guarantee an uninterrupted flow of materials. At Allstar, managing the supply chain is a critical component of our services and we are monitoring the situation closely. Check our email blasts and “News Posts” for monthly updates.

by Karla Takasumi | Nov 16, 2021 | Products

Posted November 16, 2021

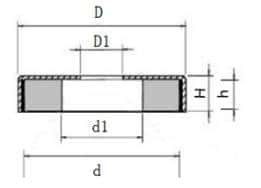

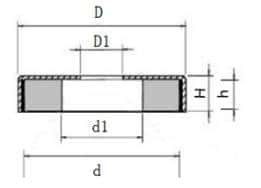

Round Base Cup Magnet Assemblies

Magnetic Assemblies are up to 32 times stronger than simple magnets by themselves.

Custom sizes, designs and coating are also available.

Product Description

1. Material: Steel cup + Ceramic ring magnet

2. Coating for steel cup: Chrome, Black Epoxy, Nickel, Zinc

3. Magnet surface lower than that of cup 0.005’’

4. Working temperature range: -40°C – 100°C

5. Packing box size: 15.0 x 10.6 x 6.3 Inches

6. We can customize the special size and coating per your requirement.

7. Pull force tested on flat steel plate ½” thick. If your steel is thinner, coated or the surface is rough or rusty, the pull force may vary. We recommend that you obtain a sample for testing.

by Karla Takasumi | Nov 9, 2021 | Industry News

Posted November 8, 2021

Rare Earth Metals Forecast

This last year has seen large fluctuations in rare earth metals pricing and some like PrNd and DyFe have more than doubled since October of last year. PrNd and DyFe are two metal components used in the manufacture of the very popular NdFeB (Neo) magnets.

In the month of October, PrNd rose by 16% and DyFe by 5% – with many factors driving the prices up including supply shortages, increased production costs and the continued growing demand.

We highly recommend that customers place blanket or other long-term contracts to guarantee an uninterrupted flow of materials. At Allstar, managing the supply chain is a critical component of our services and we are monitoring the situation closely. Check our email blasts and “News Posts” for monthly updates.

| PLATING / COATING | THICKNESS | COLOR | Tw (°C) | PRICE | INDOOR USE | ABRASION RESISTANCE | HUMIDITY | WATER | SALTY AIR | SALTWATER | GLUE ADHESION | | PRICE | INDOOR USE | ABRASION RESISTANCE | HUMIDITY | WATER | SALTY AIR | SALTWATER | GLUE ADHESION | Total |

| Passivate | 0.1-0.5 Microns | Grey | ≤230 | Low | Acceptable | Acceptable | Bad | Bad | Bad | Bad | Best | | 1 | 3 | 3 | 4 | 4 | 4 | 4 | 1 | 24 |

| Nickel (Ni-Cu-Ni) | 10-20 Microns | Silver | ≤230 | Low | Good | Good | Good | Acceptable | Acceptable | Acceptable | Acceptable | | 1 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 19 |

| Chemical Nickel (Ni-Cu-Ni-ChNi) | 10-20 Microns | Silver | ≤230 | High | Best | Good | Best | Best | Best | Best | Good | | 10 | 1 | 2 | 1 | 1 | 1 | 1 | 2 | 19 |

| Zinc (Zn) | 6-10 Microns | Silver-Gray | ≤160 | Low | Good | Acceptable | Acceptable | Acceptable | Bad | Bad | Good | | 1 | 2 | 3 | 3 | 3 | 4 | 4 | 2 | 22 |

| Gold (Ni-Cu-Ni-Au) | 10-20 Microns | Gold | ≤230 | High | Good | Good | Good | Acceptable | Acceptable | Acceptable | Acceptable | | 10 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 28 |

| Silver (Ni-Cu-Ni-Ag) | 10-20 Microns | Silver | ≤160 | High | Good | Good | Good | Acceptable | Acceptable | Acceptable | Acceptable | | 10 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 28 |

| Black Epoxy (Ni-Cu-BE) | 15-25 Microns | Black | ≤160 | Medium | Best | Bad | Best | Best | Good | Good | Acceptable | | 5 | 1 | 4 | 1 | 1 | 2 | 2 | 3 | 19 |

| Raw Epoxy (BE) | 10-20 Microns | Black | ≤160 | Medium | Best | Acceptable | Best | Best | Good | Good | Acceptable | | 5 | 1 | 3 | 1 | 1 | 2 | 2 | 3 | 18 |

| Tin (Ni-Cu-Sn) | 10-20 Microns | Silver | ≤160 | Medium | Good | Bad | Good | Acceptable | Good | Acceptable | Bad | | 5 | 2 | 4 | 2 | 3 | 2 | 3 | 4 | 25 |

| Parylene (Parylene C) | 8-15 Microns | Grey | ≤230 | Medium | Good | Bad | Good | Acceptable | Good | Acceptable | Bad | | 5 | 2 | 4 | 2 | 3 | 2 | 3 | 4 | 25 |

| Plastic (ABS) | >800 Microns | Various | ≤160 | High | Best | Best | Best | Best | Best | Best | Good | | 10 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 18 |

| Teflon® (PTFE) | 250-500 Microns | Blue | ≤230 | High | Best | Best | Best | Best | Best | Best | Bad | | 10 | 1 | 1 | 1 | 1 | 1 | 1 | 4 | 20 |

| Everlube-6155® | 8-25 Microns | Silver-Gold Satin | ≤230 | High | Best | Best | Best | Best | Best | Best | Acceptable | | 10 | 1 | 1 | 1 | 1 | 1 | 1 | 3 | 19 |

| | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | |

| Best > Good > Acceptable > Bad | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | |

by Karla Takasumi | Oct 6, 2021 | Products

Posted October 6, 2021

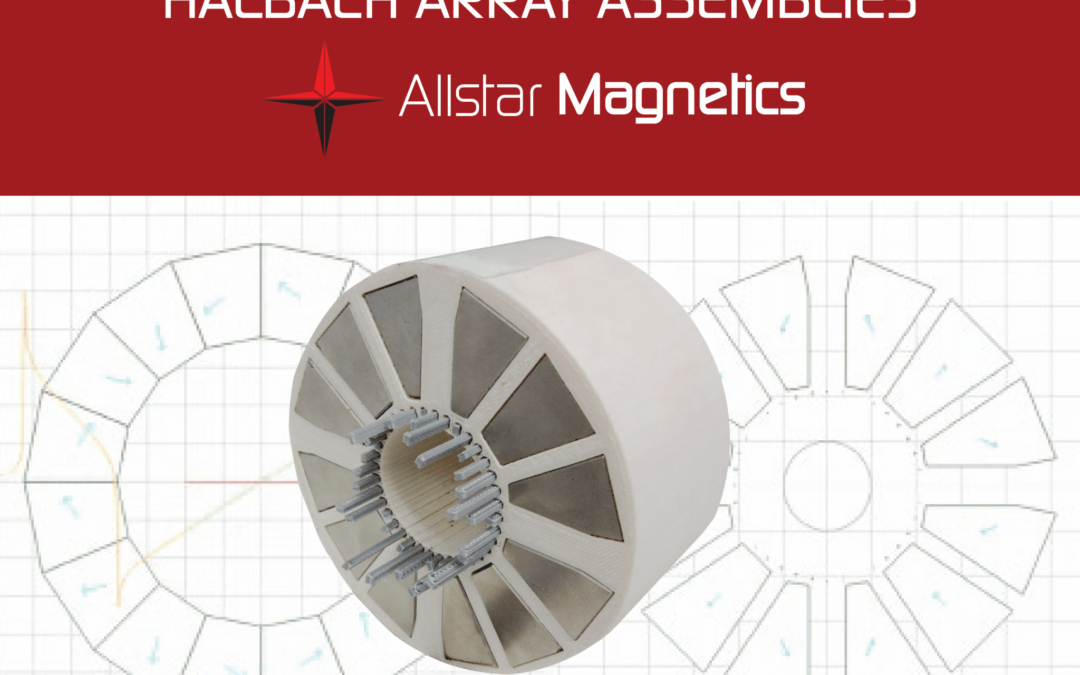

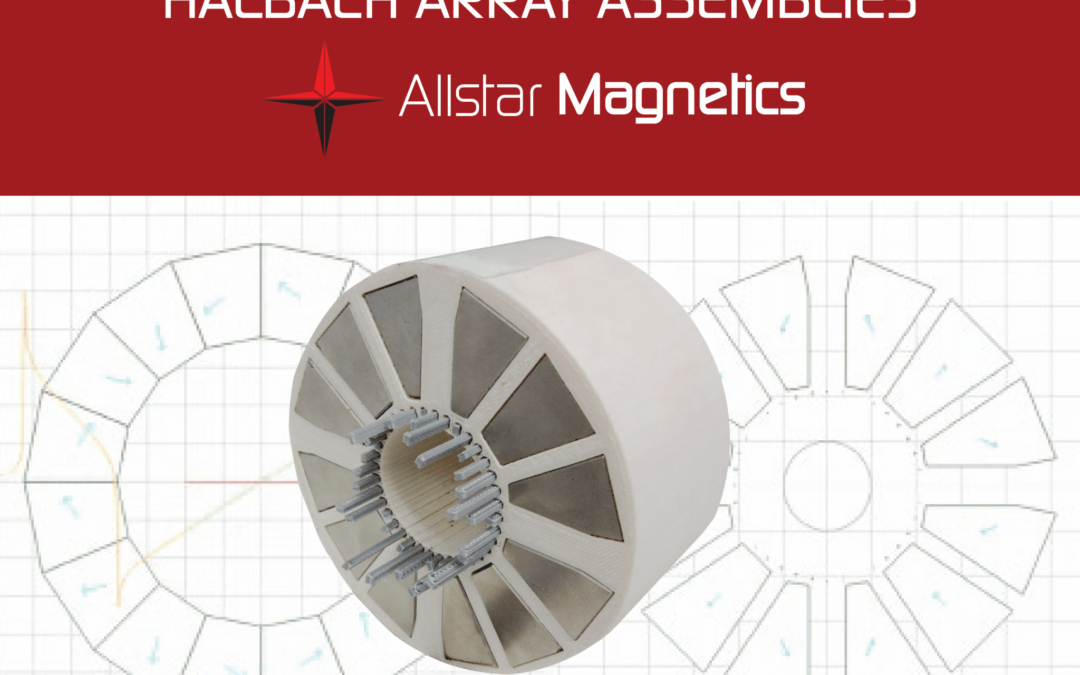

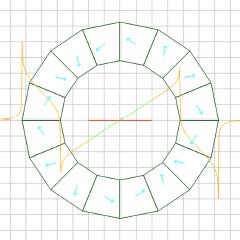

Halbach Array Permanent Magnet Assemblies

Allstar Magnetics can work with your team to design and manufacture Halbach arrays for your permanent magnet assembly needs. Halbach arrays are an arrangement of permanent magnets that concentrates the field on one side of array and has a near zero field on the opposite side. This is achieved by alternating the polarity of the magnets and forcing the path of the flux lines on one side to combine and the opposite side to cancel each other out. These assemblies can be constructed in variety of different configurations such as linear, cylindrical, or circular.

Industry Applications

Linear applications include particle accelerators, free-electron lasers, linear motors, and any movement that requires planar motion. There are a variety of design that use cylindrical arrangements for higher power density and efficiency such as NMR, high torque motors and beam focusing applications. Halbach arrays can also be used to create gradient fields to channel electrons in medical and science applications.

Manufacturing Considerations

It is important to understand the required field, air gap, temperature at operation, life of the product, adhesive outgassing, magnet performance at both temperature, magnet performance in a magnetic field, mechanical constraints, tooling, allowable fringing, weight, size and budget.

Let us know how we can help with your custom magnetic needs.

by Karla Takasumi | Apr 7, 2021 | Allstar Magnetics News

Posted April 7, 2021

Rapid Prototyping

Allstar offers rapid prototyping of custom machined permanent magnets and magnet assemblies. Companies often advertise rapid prototypes and then miss promised delivery dates. At Allstar we specialize in on-time-delivery and will meet your deadline requirements. Typical lead time is 4-5 weeks for magnets and 2-3 weeks for ferrites.

Click Here to Submit RFQ

Featured Case Studies:

At Allstar it is not just parts, it is about achieving customer satisfaction. We specialize in solving problems.

Here are a few of the more unusual solutions:

A magnetic material was obsoleted over 60 years ago and Allstar was able to provide prototypes to create the exact custom blend.

View Research & Development Case Study

Custom designed magnetic assembly was a cost prohibitive and manufacturing nightmare until the customer brought the design to Allstar – see how they solved the issues.

View Assembly Case Study

An R&D wire wound prototype was built in the lab and company struggled to find suppliers that could meet the production scale volumes – see how Allstar quickly ramped to meet the demand.

View Volume Manufacturing Case Study