by Karla Takasumi | Mar 11, 2021 | Allstar Magnetics News

Posted March 11, 2021

Rare Earth (NdFeB & SmCo), Alnico, and Ferrite Custom Magnetic Assemblies or Build-to-Print

Did you know that Allstar is a vertically integrated manufacturer of both permanent magnet assemblies and soft magnetic wound parts?

Allstar uses depth of knowledge, superior customer service and excellent on time delivery to streamline critical elements of the product lifecycle for both soft magnetics and permanent magnet applications. Focusing on crucial value-added needs like inventory stocking, design, prototyping, and volume solutions, has helped Allstar Magnetics remain a leader in next generation magnetic applications.

For our customers looking for custom wound assemblies, we have the equipment and engineering support to produce quantities from prototype to full high-volume production. Allstar Magnetics stocks a large selection of ferrite cores and hardware as well as custom assemblies tailored for quick turn and rapid prototypes.

Why choose Allstar? We offer quality, speed, and engineering experience all with great customer service. Understanding the best way to specify magnets, hardware and test magnetic assemblies is a key support feature we offer.

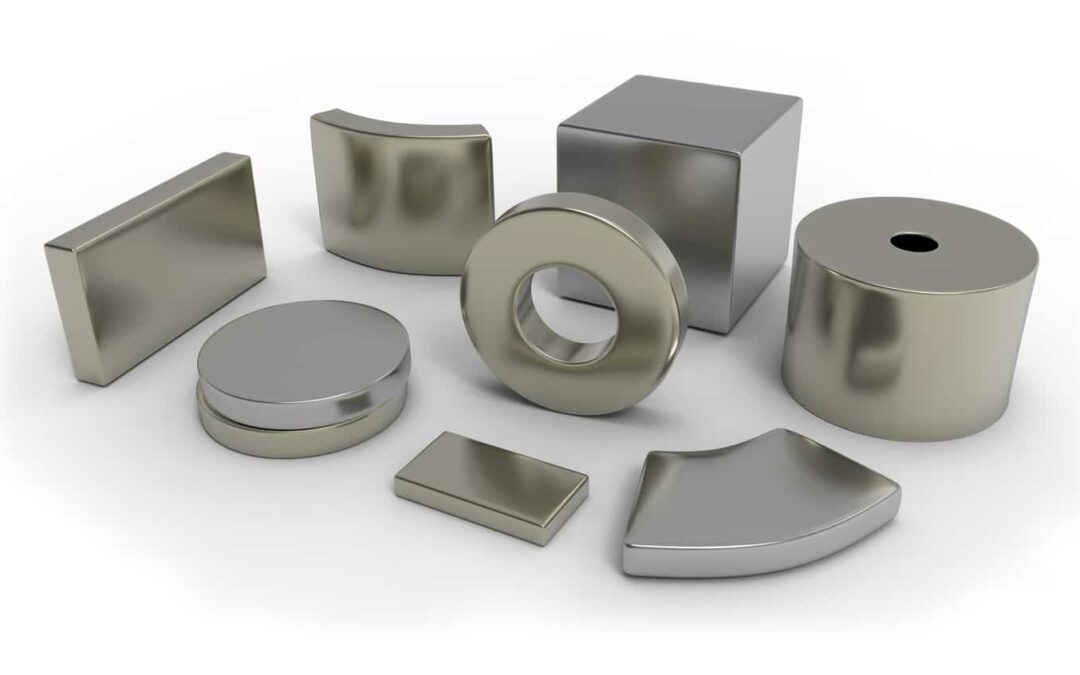

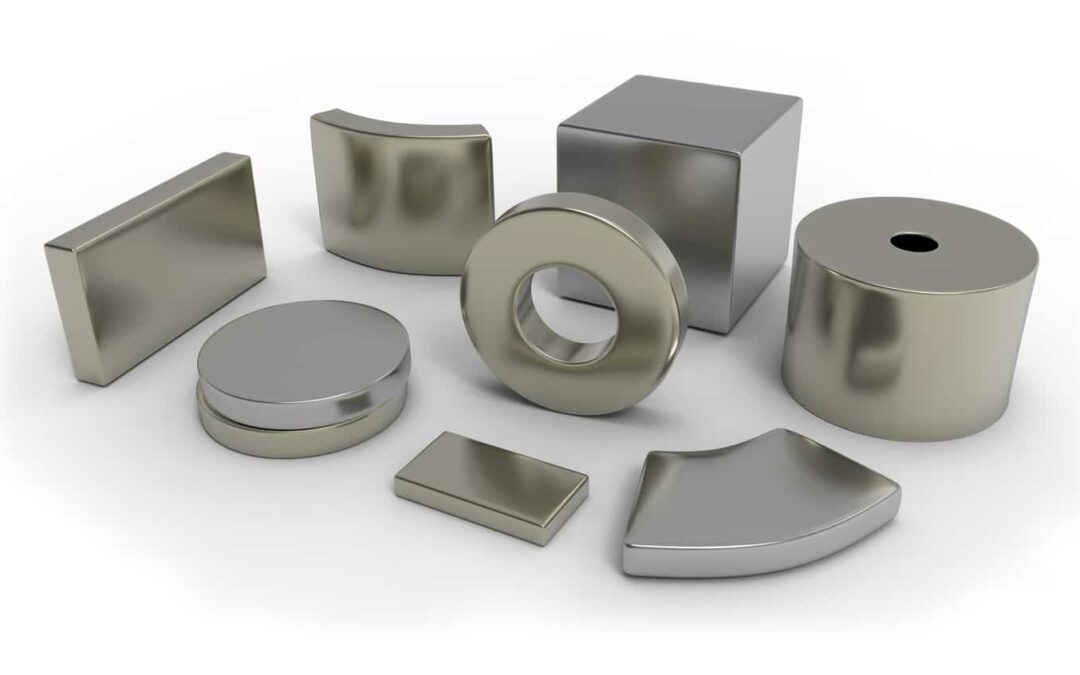

Permanent Magnet Assemblies

Allstar Magnetics specializes in permanent magnet such as Alnico, Neodymium, Samarium Cobalt, Ceramic, Bonded Magnets, Magnetic Separators, Magnetic Assemblies, Radial Rings & Linear Magnetic Tracks.

Custom Wound Assemblies

Allstar features Ferrite Cores, Custom Machined Cores and Custom Wound Transformers, Inductors & Coils.

by Karla Takasumi | Mar 10, 2021 | Allstar Magnetics News

Posted March 10, 2021

Allstar’s custom CNC machining is the best solution for applications where standard, catalog cores do not meet your requirements. Our Haas CNC 4-axis milling machine can grind to those special shapes and sizes for your custom applications. Prototyping and small to large production runs available.

Machining workmanship includes:

- Quick-turn Prototype Development

- Grinding, Slicing and Milling from Larger Blocks

- Surface Finish and Polishing

- Gluing and Assembly Operations

- Custom Packaging

Are you looking for a certain air gap or AL-value or maybe a slotted toroidal core?

Are you looking for a certain air gap or AL-value or maybe a slotted toroidal core?

Gapping Specifications and Services:

- Al Value Gap Tolerance of ±3% or Better and Mechanical Gaps of ±0.0005 or Better

- Precision Inductance Testing

- Custom Protective Packaging of Gapped Cores

View Machined Ferrite Services

by Karla Takasumi | Mar 3, 2021 | Industry News

Posted March 3, 2021

At Allstar we understand your need to have a reliable and consistent supply chain, so we closely monitor the prices of rare earth metals and other materials used for permanent magnets. In the last several months there has been a notable uptick in metals pricing that is having an impact on magnet costs.

| Date |

Cobalt |

Neo |

Terbium |

DyFe |

Copper |

| Nov 2020 |

4% |

8.5% |

2% |

5.5% |

3% |

| Dec 2020 |

24% |

15% |

5% |

16% |

16.6% |

| Feb 2021 |

37% |

29% |

36% |

32% |

20% |

Data as of 2/25/21 Data source Zhaocicai.com

While it is difficult to predict how this volatility will impact the long-term pricing in the permanent magnet market, Allstar is proactively offering solutions to help you mitigate risk and lock in pricing to ensure just-in-time delivery. Allstar has blanket agreements with flexible inventory, warehousing and stocking arrangements.

Contact your Allstar sales rep today to secure your uninterrupted supply chain.

by Karla Takasumi | Mar 2, 2021 | Allstar Magnetics News

Posted March 2, 2021

AS9100 is an internationally recognized standard that certifies companies meet the requirements in AS9100D – Aerospace regulatory control for safety, reliability, and maintainability. AS9100 incorporates all aspects of ISO 9001 so compliance assures a quality management system (QMS) plus sections on product realization, design and development, supplier control, product monitoring and measurements. AS9120B is certification for companies that procure parts, materials, and assemblies for distribution to the Aerospace industry.

Allstar has been AS9100 and AS9120 (2017) and is ITAR registered and a proud supplier to the defense and aerospace industry. We understand magnetic applications, specifications, and distribution requirements needed to meet the demands of aerospace customers.

Contact us today for build-to-print, prototype, and custom magnet systems in permanent magnets, soft magnetics, and custom-wound magnetics (transformers, inductors, and coils).

View Certifications

Looking for a Reliable, On-Time Magnetic Partner?

Frustrated with Missed Deliveries or Long Lead Times for Magnets?

Allstar Magnetics is now under new sales management that understands the need for holding inventory and offering just-in-time deliveries. We focus on speed, service, and commitment to promise dates.

by Karla Takasumi | Feb 18, 2021 | Manufacturer Updates

Posted February 18, 2021

The following Ferroxcube E-core products will have a change in tooling design by introducing chamfers:

– E71/33/32

– E55/28/25

– E55/28/21

– E56/24/19

– E42/21/20

– E42/21/15

The change will be reflected in the visual appearance of the core. The chamfers will not affect functionality of the cores, however handling and winding properties are expected to improve.

Products with new appearance will be delivered gradually from March 2021 onwards depending on the inventory level of current cores. In the transition period both types of chamfers might be delivered together.

View more information here:

Product Change Notifications