TAILOR-MADE LINEAR TRACKS

Applications of Custom Linear Tracks

in Precision Environments

Applications for custom linear track can range from use in precision manufacturing cells such as wafer manufacturing or clinical lab testing to end products such as operating beds, tables and stages for MRI and CT scanners. Linear systems are ideal for applications requiring precise alignment and positioning, such as diagnostic sample transport, food processing, vision systems, industrial automation, and collaborative robot (cobot) machine tools.

The definition of linear motion is to move an object in a straight line. Linear motion systems can include motors, drives, couplers, actuators, sensors, bearings, slides, tracks, and other hardware components. When precision in motion control and positioning is critical, commercial off-theshelf (COTS) solutions often fall short. Linear tracks are a prime example, where COTS tolerances may not meet the rigorous demands of high-performance systems.

From Concept to Manufacture:

A Customized Approach

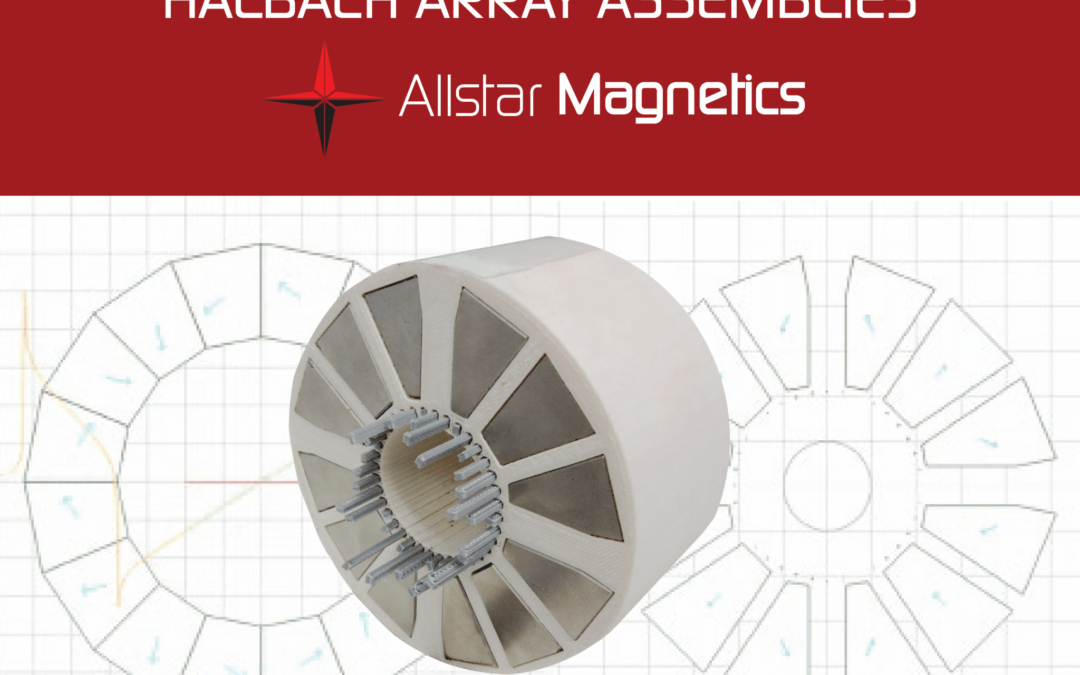

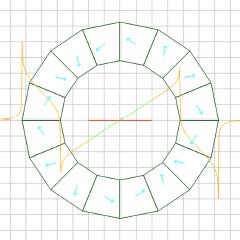

Since 1989, we have specialized in the development and manufacturing of custom magnetic solutions utilizing neodymium magnets and stainless steel. Our expertise lies in building complex magnet assemblies and systems.

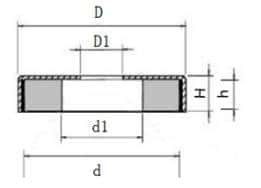

We utilize custom CNC tapping and specialtygrade steel backings to ensure structural integrity. Whether it’s flat or u-channel linear magnetic designs, , we refine concepts into manufacturable designs. We also take into account temperature and environmental effects on manufacturing processes, as well as adhesive specifications for varying environmental conditions such as humidity, heat, and outgassing, and their impact on machining tolerances. Our proprietary process is not only cost effective but also highly repeatable. Our unique approach allows us to provide customers with custom-built and staged linear motor tracks tailored for highly accurate motion control and positioning systems on demand.

Dynamic Performance in Custom

Linear Motion Systems

Linear motion systems have a wide range of dynamic performance. By customizing the motor and direct drive systems, high speed and acceleration can be achieved with exceptionally smooth velocity regulation and low ripple. They can also be customized to handle heavy or bulky load applications. Overall, linear systems have a lower cost of ownership due to less moving parts, reduced mechanical wear and reduced system operating costs.

The Cost vs. Performance Trade-off in

Custom Design

Designing a custom linear track involves a critical trade-off between cost and performance. COTS tracks are inexpensive but are limited to standard lengths, standard flat and U-channel sizes and set tolerances for position accuracy. Custom linear tracks requires design time, custom tooling, and custom manufacturing processes. If the volumes are small to medium, then the solution might not be cost effective unless you consider the total cost of ownership.

Many high-volume contract manufacturers do not have the experience or the safety training to handle strong rare earth magnets that are part of the sub-assemblies. There are safety, training, and manufacturing consideration when working with rare earth magnets.

Custom Linear Tracks For a Wide

Range of Applications

- Diagnostic Sample Transport

- Food Processing

- Custom Assembly Processes

- Robot/Cobot Systems

- High Load Applications